leeb hardness testing method|leeb converted to butt section : dealer Scope. 1.1 This test method covers the determination of the Leeb hardness of steel, cast steel, and cast iron (Part A), including the methods for the verification of Leeb hardness testing instruments (Part B), and the calibration of standardized test blocks (Part C). This protocol is for obtaining a glucose stock solution at various concentrations. Note: Glucose stock solutions typically show slight degradation upon autoclaving (indicated by color change), so sterilization through a 0.22μm filter is .

{plog:ftitle_list}

The guidance provides recommendations for certain Class III device manufacturers whose devices are sterilized by EtO, and that might be or are affected by potential, actual, or .

Scope. 1.1 This test method covers the determination of the Leeb hardness of steel, cast steel, and cast iron (Part A), including the methods for the verification of Leeb hardness testing instruments (Part B), and the calibration of standardized test blocks (Part C). Scope. 1.1 This test method covers the determination of the Leeb hardness of steel, cast steel, and cast iron (Part A), including the methods for the verification of Leeb hardness testing instruments (Part B), and the calibration of standardized test blocks (Part C).

The Leeb hardness testing, otherwise called as Leeb Rebound Hardness Test (LRHT), is considered as one of the four commonly used methods to test the hardness of the metal. It is a type of non-destructive testing used to inspect large sized workpieces weighing above 1 kg.The Leeb Rebound Hardness Test (LRHT) invented by Swiss company Proceq SA is one of the four most used methods for testing metal hardness. This portable method is mainly used for testing sufficiently large workpieces (mainly above 1 kg).3.1.3 Leeb hardness test—a dynamic hardness test method using a calibrated instrument that impacts a spherically shaped tungsten carbide, silicon nitride, or diamond tipped body with a fixed velocity (generated by a spring force) onto a surface of the material under test.

1.1 This test method covers the determination of the Leeb hardness of steel, cast steel, and cast iron (Part A), including the methods for the verification of Leeb hardness testing instruments (Part B), and the calibration of standardized test blocks (Part C). 1.2 The values stated in inch-pound units are to be regarded as the standard.The Leeb hardness testing method uses a conical indenter and ball indenter to measure the hardness of a material. This article explains how this method works and its applications.

ISO 16859-1:2015 covers the determination of a dynamic hardness of metallic materials using seven different Leeb scales (HLD, HLS, HLE, HLDL, HLD+15, HLC, HLG).

Leeb hardness testing is a dynamic and robust method employed for determining the hardness of steel products, cast steel, and cast iron. Governed by the ASTM A956/A956M standard, this method utilizes the Leeb hardness principle to deliver fast and accurate measurements essential in various applications, from quality control to on-site metal .Determination of the hardness of metallic materials according to Leeb is defined in the ISO 16859 and ASTM A956 standards. In this dynamic test method, the ratio of rebound velocity to impact velocity of a moving impactor is used to determine the hardness.

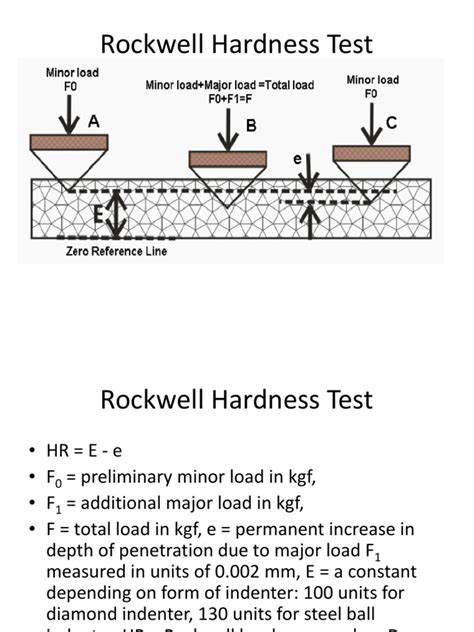

units for rockwell hardness test

iso 8655 pipette specifications

ISO 16859 consists of the following parts, under the general title Metallic materials — Leeb hardness test: — Part 1: Test method. — Part 2: Verification and calibration of the testing devices. — Part 3: Calibration of reference test blocks. Scope. 1.1 This test method covers the determination of the Leeb hardness of steel, cast steel, and cast iron (Part A), including the methods for the verification of Leeb hardness testing instruments (Part B), and the calibration of standardized test blocks (Part C).

The Leeb hardness testing, otherwise called as Leeb Rebound Hardness Test (LRHT), is considered as one of the four commonly used methods to test the hardness of the metal. It is a type of non-destructive testing used to inspect large sized workpieces weighing above 1 kg.The Leeb Rebound Hardness Test (LRHT) invented by Swiss company Proceq SA is one of the four most used methods for testing metal hardness. This portable method is mainly used for testing sufficiently large workpieces (mainly above 1 kg).3.1.3 Leeb hardness test—a dynamic hardness test method using a calibrated instrument that impacts a spherically shaped tungsten carbide, silicon nitride, or diamond tipped body with a fixed velocity (generated by a spring force) onto a surface of the material under test.

1.1 This test method covers the determination of the Leeb hardness of steel, cast steel, and cast iron (Part A), including the methods for the verification of Leeb hardness testing instruments (Part B), and the calibration of standardized test blocks (Part C). 1.2 The values stated in inch-pound units are to be regarded as the standard.The Leeb hardness testing method uses a conical indenter and ball indenter to measure the hardness of a material. This article explains how this method works and its applications.

iso 8655-2 pipette

ISO 16859-1:2015 covers the determination of a dynamic hardness of metallic materials using seven different Leeb scales (HLD, HLS, HLE, HLDL, HLD+15, HLC, HLG). Leeb hardness testing is a dynamic and robust method employed for determining the hardness of steel products, cast steel, and cast iron. Governed by the ASTM A956/A956M standard, this method utilizes the Leeb hardness principle to deliver fast and accurate measurements essential in various applications, from quality control to on-site metal .Determination of the hardness of metallic materials according to Leeb is defined in the ISO 16859 and ASTM A956 standards. In this dynamic test method, the ratio of rebound velocity to impact velocity of a moving impactor is used to determine the hardness.

types of rockwell hardness test

iso accredited pipette calibration

An autoclave is used primarily for sterilization, using high-pressure steam to kill microorganisms. On the other hand, a retort is a vessel used to heat substances and produce reactions, with a .

leeb hardness testing method|leeb converted to butt section